Lactalis

Pimcore Lactalis Group Website Redesign

How to improve data quality in the food industry

Lactalis is the world’s leading dairy group, with four major brands – President, Galbani, Lactel, Parmalat – while also supporting and investing in local brands. Lactalis is number one in cheese, number three in refrigerated dairy products, and number three in consumption milk.

- Dedicated experts

- Project Manager / Scrum Master

- Consultant / Business Expert

- Technical Expert

- Back-end Developer

- Technologies

- Pimcore

Most reliable data for society as a whole

Lactalis wanted to create a global database for all group products with reliable information from factory to customer. The information would be published to internal (ERP, WMS) and external (GDSN, LSP) information systems. The main challenge for Lactalis was to eliminate obstacles to business development by creating and maintaining a group product catalog – a new information management system. Additionally, stakeholders would need to take responsibility for information input and confidentiality. Eliminating duplicate/triple entries and improving information sharing were also project objectives. The PIM needed to be flexible enough to adapt to evolving regulations in the food industry.

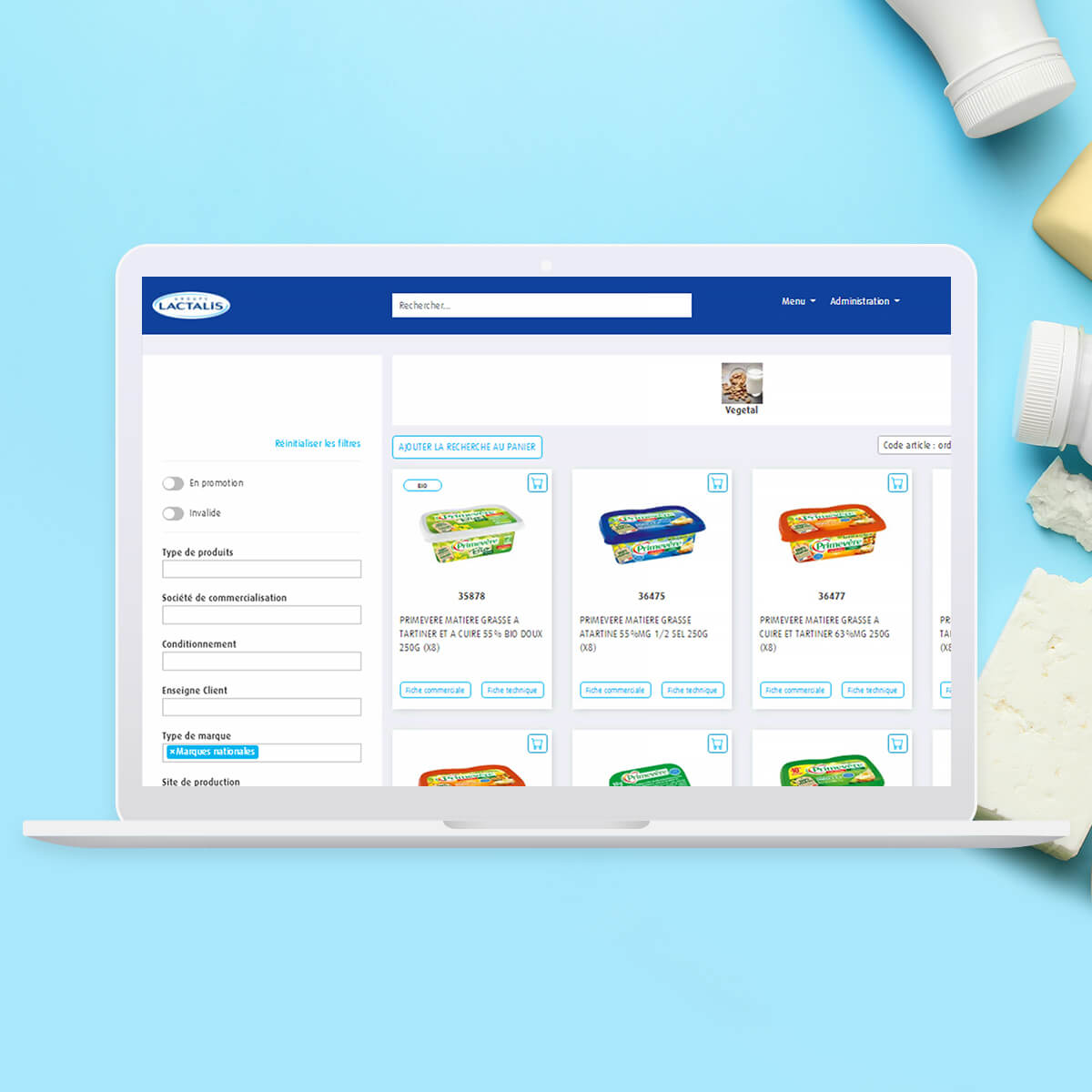

A single digital platform to manage everything

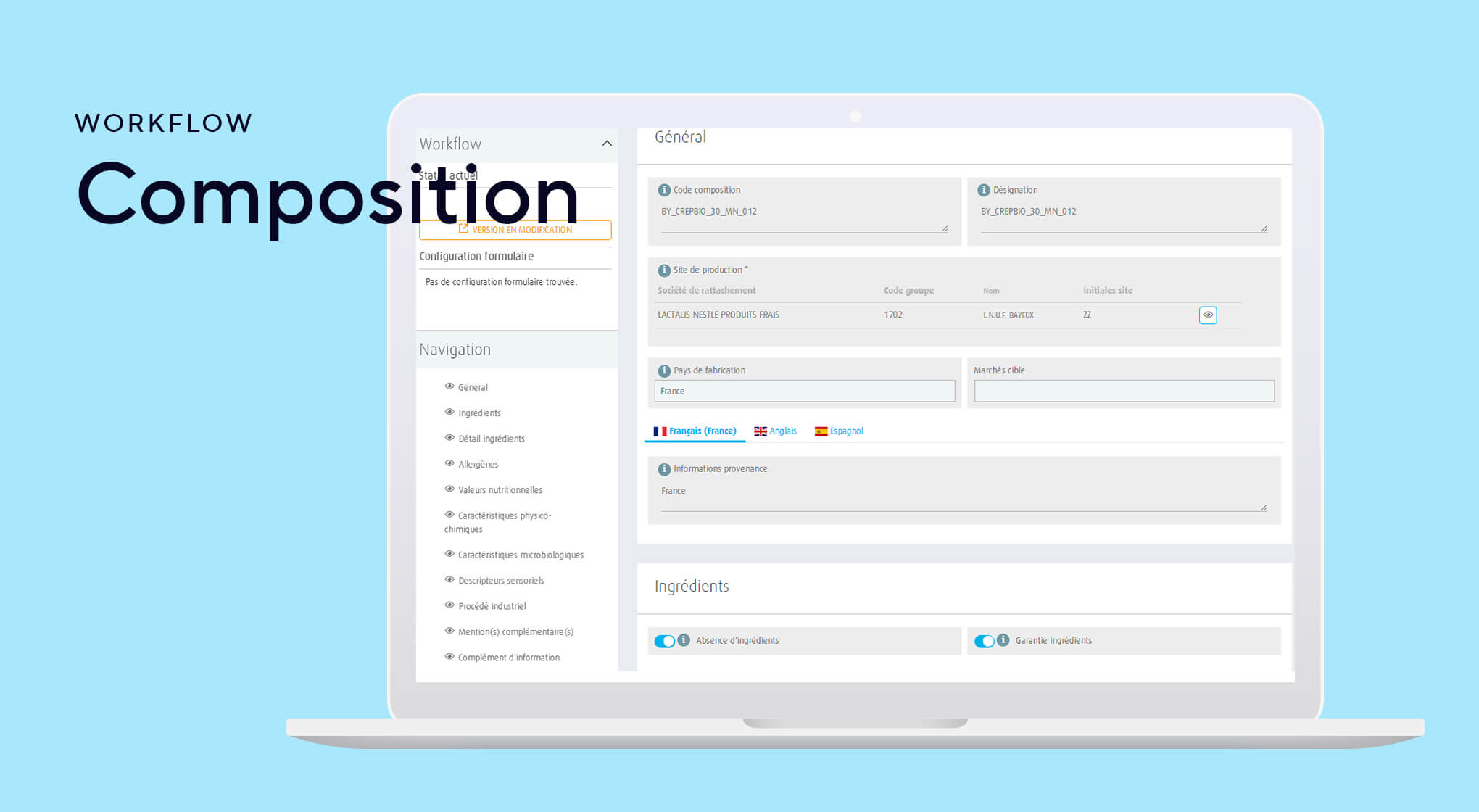

Thanks to Pimcore’s multi-domain capabilities, it has been possible to define and manage all objects related to a product: recipes, factories, packaging, and even advertising licenses!

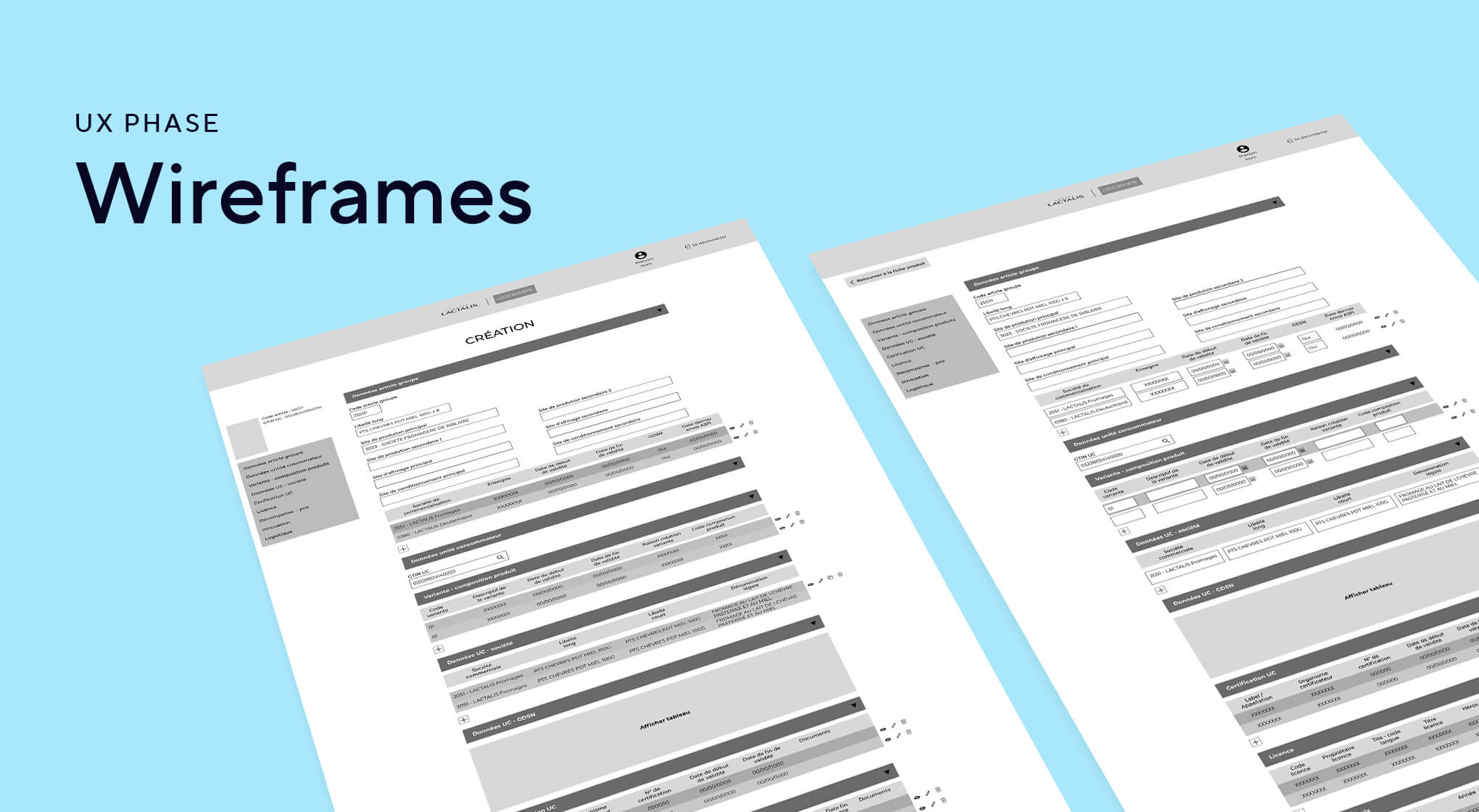

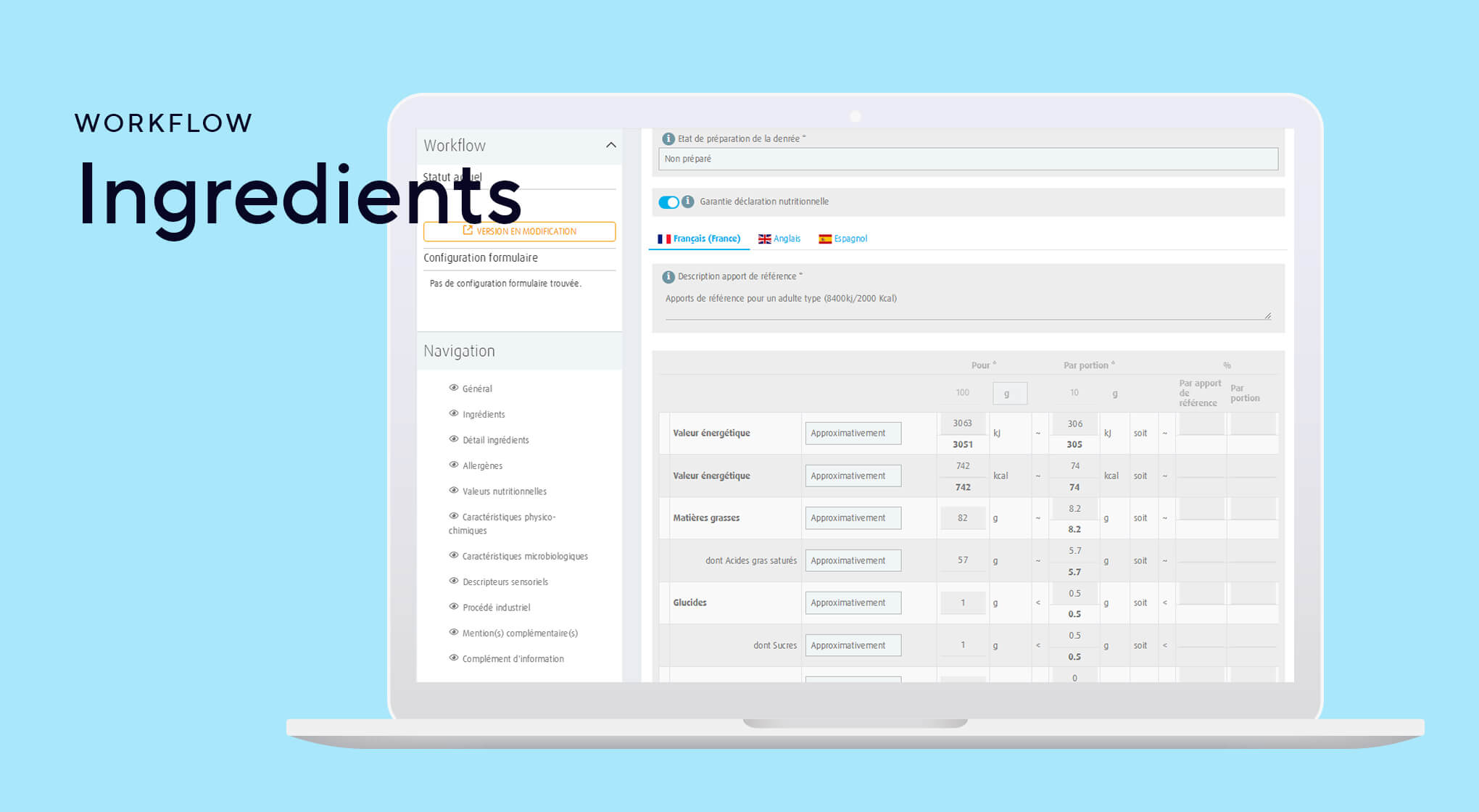

The customizable platform has allowed DATASOLUTION to create specific functionalities (form generator, business rules…). The integrated workflow engine was used to design and implement the complex data validation process, throughout the product creation flow.

Facilitating data entry and control

The DATASOLUTION team also developed dedicated screens and processes to facilitate data entry and control (such as the ingredient table). An SSO connector with Lactalis’ Active Directory was implemented to facilitate the integration of new users.

Key figures of the projet

duplicated data

data objects

attributes

Centralized and reliable information

Lactalis has observed a clear improvement in the quality of information across the 4 entities where the PIM has been deployed. Data entry has been simplified within the group, particularly in factories (with up to a 60% reduction in the number of palletization patterns in certain areas).

Product teams can now have better visibility on the creation process, including potential bottlenecks. The PIM is now connected to multiple internal systems, including SAP. Technical and commercial sheets are available “on-the-fly” through the PIM. Practices are now harmonized across divisions.

Lactalis can now produce its first key performance indicators related to product creation. A user group has been established to define all PIM evolutions and review/improve all processes.

Interested in this project type?

Contact us